Wholesale Wedding Flowers: Proven Bulk Options That Arrive Photo-Perfect?

I see budgets slip when boxes arrive crushed or colors do not match. Crews panic. Photos suffer. I fix it with simple SKUs, smart packs, and fast tests.

Yes. Wholesale wedding flowers can arrive photo-perfect. Pick winning SKUs, lock pack ratios, run a 48-hour sample cycle, ship with clear Incoterms, and verify quality with swatches, pull tests, and photo checks.

This guide keeps your wholesale wedding flowers consistent from sample to install, so crews work faster and editors spend less time fixing color.

I write this for buyers who own outcomes. You want zero-drama installs and calm photos. You also want steady margin. I show what works for me in real B2B orders. I use simple words. I give short steps. I add stories from past projects, so you can see the path and avoid waste. For fast browsing, open our Catalog and Contact tabs.

Winning Wedding SKUs (2025 Palettes & Textures)?

I watch planners lose time when stems look plastic or shades clash. Guests notice. Edits increase. I stop that with tight SKUs and clean palettes.

Choose five repeatable palettes, three bouquet bases, and two textures per set. Keep stems in one finish family. Use the same sheen across parts to avoid mismatched light.

The way I pick winners

I keep it simple. I build each set around one hero bloom and one support bloom. I add one airy filler. I match greenery tone to the venue light. I avoid mixed sheens in one arrangement. I use soft-touch petals for hero shots. I use PE for structure and shape. I avoid heavy scent prints because cameras show the gloss. I stay in five palettes that work in most venues: ivory-champagne, blush-peach, dusty-rose, sand-taupe, and sage-olive. I also keep one bold option for brand clients, like burgundy with stone. For color cues and staging angles, I refer clients to How to Style Artificial Flowers (Retail Guide).

I hold each palette under daylight and under warm LEDs. I photograph at one meter and three meters. I check color shift. I name each palette with a short code. I label cartons with that code. When projects move outdoors, I cross-check UV notes from Best Fake Plants for Outdoors (2025).

I learned this in a resort job in Dubai. The planner needed 60 aisle bouquets and two arches. I offered a blush-peach set with soft-touch peonies, PU roses, and matte eucalyptus. I kept all parts in a satin finish. The video team thanked me. The frames looked clean with no glare. For material vocabulary that your team can reuse in pitches, I share Faux Greenery Meaning & Use Cases.

I also build texture rules. I use one matte leaf, one semi-matte filler, and one soft-touch hero. I avoid double-gloss. I avoid double-matte in dark halls. I lock the combination so reorders look the same six months later. These choices make wholesale wedding flowers look natural on camera and in person.

Pack Ratios & Carton Plans to Cut Damage?

I see damage rise when mixed SKUs shift in transit. Corners crush. Petals bend. Returns grow. I stop this with a small set of ratios and stable cartons.

Use fixed inner ratios that mirror how teams build sets. Add ribbed sleeves, corner rails, and air gap rules. Keep carton density consistent so pallets stack without crush.

How I build cartons that survive

I design the pack from the install backward. I ask what one table needs. I ask what one aisle needs. I set inners to match that count. For example, one aisle set might use eight mini bouquets and two extra stems. I pack exactly that in one inner. I add a printed build card on top. I wrap bouquets in ribbed kraft sleeves to keep edges clean. I add a soft collar for each head. I use PE caps on wires.

I use double-wall cartons for bouquets and arches. I add corner rails made from recycled board. I secure inners with paper ties. I hold the air gap at 12–18 mm so parts do not rub but also do not rattle. I place silica gel in coastal routes. For drop and vibration basics, I follow ISTA 3A handling principles.

I did this for a Canadian rental company. Their damage rate dropped by half after I moved to rails and fixed inners. Their crews stopped hunting for missing stems. They finished installs 20 minutes faster per aisle. The buyer said photos looked sharper because petals were not bent. This is why my wholesale wedding flowers cartons look boring but land clean.

I apply the same logic to bulk wedding flower walls. I align panels in a book fold. I place leaf faces inward to protect the finish. I add a rigid backer between layers. I label panels left-to-right to guide crews. The wall goes up faster. The panels do not warp. For cleaning and reset after events, teams can follow our How to Clean Artificial Flowers: 5 Easy Methods guide.

Sample → Pilot → PO: Your Fast Path (48-hr sampling window, courier options)?

I see weeks lost in slow samples. Teams wait. Launch dates slip. I cut that with a two-day rule and clear couriers.

Lock a 48-hour sample turn. Approve by photo and live swatch. Run a one-venue pilot before a full PO. Use fast couriers with predictable import steps.

What my fast path looks like

I keep a sample shelf ready. I hold the five core palettes. I also hold the top greenery SKUs. When you send a brief, I assemble the set the same day. I film a short video. I shoot the set under warm and daylight tones. I pack swatches of petals and leaves. I add a small section of wire with the same gauge as production. I share tracking.

Day two, your team opens the box. You check the petal feel. You check the sheen. You bend the wire. You hold it near your lens. If it passes, we move to a pilot. The pilot is a small live run. It might be one aisle and one arch. It might be a studio shoot. We push the pieces under real light. We time the setup. We watch for any weak points.

I did this for a UK planner with a very tight calendar. She needed a fast launch for a summer venue. We used a two-day sample. We ran a pilot in her studio that weekend. We saw that one filler had a slight glare at 3200K. I swapped it for a matte version before the PO. The event looked clean. The edit time dropped. The client rebooked.

I ship samples by DHL or FedEx from China. For import steps and brokerage, I point teams to DHL Customs Support and FedEx International Shipping Tools. I include HS codes on the slip, based on WCO HS guidance. This is how wholesale wedding flowers sampling stops being a bottleneck.

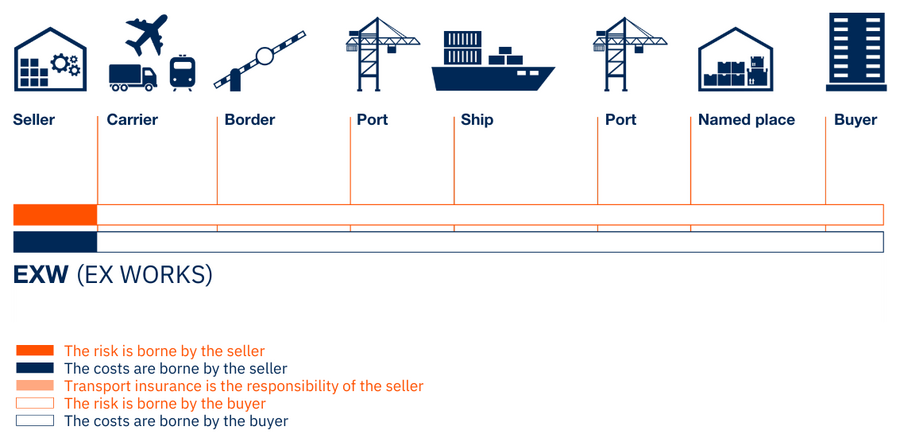

Logistics & Incoterms (FOB, DDP) and What U Actually Pay?

I see buyers shocked by hidden fees. Quotes look low. Landed cost goes high. I make the math simple and clear at the start.

Pick Incoterms by risk and speed. Use FOB for freight control. Use DDP for peace of mind. Always add pallets, insurance, duties, and last-mile to see the real number.

How I make landed cost honest

I write the quote in two versions. I give FOB Ningbo or Shanghai. I give DDP to your city. I show carton counts, CBM, and gross weight. I list pallet needs. I list the HS code and duty guess. I add an insurance line when the route is long or the season is wet.

If you pick FOB, your forwarder runs the boat or air leg. You see the freight bill. You see the local fees. If you pick DDP, I run the full chain to your door. You get one number. You do not chase brokers. You do not chase storage fees. The cost is higher. The stress is lower. Many wedding clients like this during peak months.

I supported a U.S. rental warehouse that was short on staff. They picked DDP for two months. They needed a calm calendar. I used air for bouquets and sea for arches. I staged departures, so they always had stock. They paid more on shipping but saved on rush labor and missed shoots. They then moved back to FOB in the off season.

I include a small buffer in the plan. I prefer to beat the number. I never hide fuel surcharges. I write them down. When teams want to check definitions, I send the ICC Incoterms® explainer. I also explain when air makes sense. For example, a late add-on for boutonnières can go by air while arches sail. I calculate landed cost for wholesale wedding flowers in a single sheet, so finance and ops stay aligned.

Quality Control: Swatches, Pull Tests, Photo Checks?

I see trouble when QC is only a text message. Colors drift. Wires fail. Finishes shine. I guard against this with three simple checks.

Approve with swatches. Pull test every stem. Photo check each batch under two lights. Reject fast if any part fails.

The checks I trust

I start with swatches. I send a petal and a leaf from the exact lot. I write the lot code. You sign that code in email. We now share the same color and sheen reference.

I move to pull tests. I set a simple rule. I pull each wire joint to a target force by hand. I bend the head five times. I check for wobble. I check for glue bleed. If it fails, I stop the line. I adjust glue, heat, or wire gauge. I log the fix.

I finish with photo checks. I have two light rigs. One is 5600K. One is 3000K. I shoot the set with both. I stand one meter away. I stand three meters away. I look for glare and color shift. I also check for lint and dust. I clean the lens. I wipe the petals. I keep it real because the camera sees everything. For care after delivery, I ask crews to follow How to Clean Artificial Flowers: 5 Easy Methods to hold color and shape.

I did these steps for a hotel group in Australia. The lobby had warm lamps. The ballroom had colder light. The arches looked great in one room and odd in the other. I caught it in checks. I changed one filler to a matte type. I added a soft-touch top layer on the hero bloom. The pieces worked in both rooms. The planner did not waste time on edits.

I keep photos and notes in a shared folder. Your team can see the pass images and the codes. If you reorder in six months, I pull the same codes or I warn you if a supplier changed a base. I do not guess. I tell you early. This is how I keep imitation wedding flowers consistent across seasons within larger wholesale wedding flowers programs.

Buyer Scenarios — Quick Reminders (for search and clarity)?

Teams ask for shortcuts they can reuse across sites. I give a compact list that fits in a SOP.

Use these prompts when you plan, quote, or restock. They help search and remind crews what to do next.

- When a venue expands headcount, I switch from ad-hoc orders to wholesale wedding flowers so crews build faster with repeatable parts.

- When a planner needs brand consistency across cities, I lock palettes in wholesale wedding flowers to match light and finish.

- When a retailer tests an events aisle, I pilot with wholesale wedding flowers to prove margin and reduce shrink.

- When a content team schedules back-to-back shoots, I stage extra stems from wholesale wedding flowers so reshoots do not stall.

- When logistics windows are tight, I split ship wholesale wedding flowers by air for bouquets and sea for arches.

- When a client wants low-maintenance décor, I spec UV-aware wholesale wedding flowers and share the cleaning SOP.

- When a hotel renovates lobbies, I standardize wholesale wedding flowers by floor so housekeeping follows one reset routine.

- When a rental brand scales, I pick durable frames and soft-touch heads in wholesale wedding flowers to survive turnover.

- When a buyer optimizes cash flow, I plan quarterly POs for wholesale wedding flowers and align pallets to store height.

- When a store needs seasonal looks fast, I rotate color caps within wholesale wedding flowers without changing the base build.

Procurement Notes — Quick Wins?

I keep a few habits that save budget and time on repeat orders. They are simple. They work in busy calendars.

Lock specs once. Stage buffers. Train teams on the same boxes and motions. Keep the language short and clear.

- For new venues with tight ramps, I preload wholesale wedding flowers by palette, so crews can build tables and arches without last-minute hunting.

- For e-commerce shoot weeks, I stage a spare carton of wholesale wedding flowers to cover styling changes or prop losses between scenes.

- For rental turnarounds, I standardize on durable frames and soft-touch heads within our wholesale wedding flowers line to survive repeat packing.

- For seasonal resets, I rotate only accent tones while keeping base wholesale wedding flowers constant, so listings and training stay simple.

- For budget control, I book quarterly POs of wholesale wedding flowers and align pallet heights to racking, which cuts storage waste.

- For cross-city brand work, I lock one spec sheet for all wholesale wedding flowers, so every site delivers the same look under different lights.

Conclusion

Pick tight SKUs. Pack smart. Sample fast. Ship on clear terms. Check color and strength. Your wholesale wedding flowers then land calm and look sharp.

Ready to move?